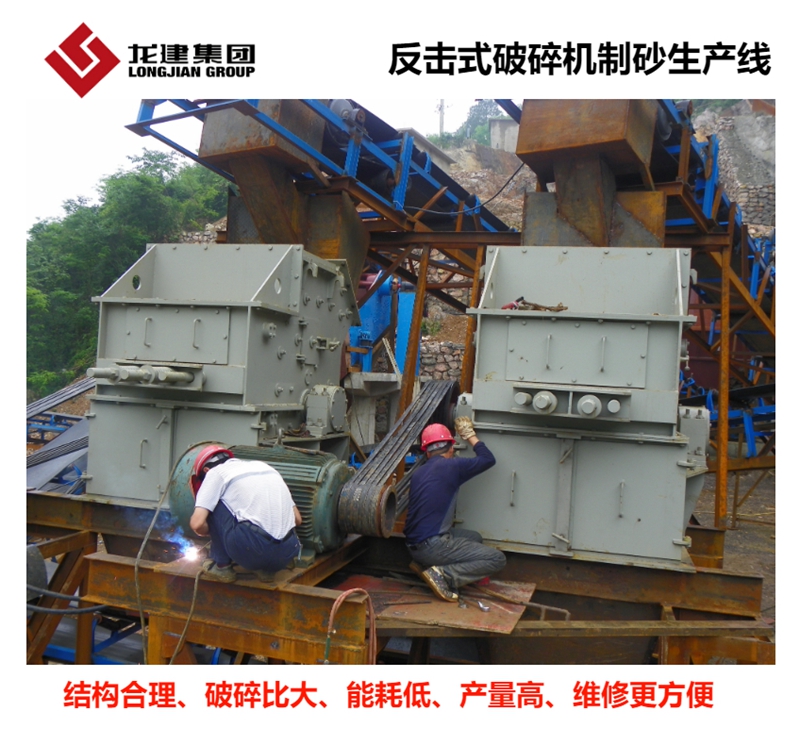

With the rapid development of my country's economy, in the late 1980s, my country introduced KHD hard rock impact crusher and made it domestic, but its core parts, hammers, depended on imports. For this reason, the localized hammers were listed as the key scientific research projects during the "Eighth Five-Year Plan" period. The breakthrough of wear-resistant materials makes the stone processed and produced by the hard rock impact crusher fully meet the requirements of highway anti-skid pavement concrete. Subsequently, the impact crusher became an indispensable condition for bidding for highway and other transportation construction. At the time when many crusher manufacturers developed this equipment, Sanming Heavy Industry, a subsidiary of Chongqing Longjian Group, successfully launched PCF impact hammer crusher series, PFY-Ⅱ impact crusher series and many other types of impact crushers. Once available, it has been recognized by many users. Here, the editor of Longjian Group discusses the maintenance and maintenance of the impact crusher in the machined sand production line.

1. Implement regular inspection and maintenance

After the new machine is put into operation, the impact crusher will be inspected at the end of each shift; the motor and lubrication will be inspected once a week after operation, including the tightening scenario of the constant parts, belt drive, bearing seal, and impact lining , All-round inspection of the wear scenario of the lining board, and establish inspection and maintenance and replacement rail system.

2. Reasonably adjust the gap between the rotor and the counter lining

When the rotor of the impact crusher is in operation, the gap between the rotor and the impact liner cannot be adjusted. If the pieces of material stay between the impact plate and the shell, it is recommended to lift the impact frame slightly between the readjustment gaps, so that the block of feed will become loose and the impact frame is easy to adjust. If the counterattack is not enough, you can pat on the loose lever (protected with a wooden board), the gap between the rotor and the counterlining is completed by the adjustment device of the machine, first loosen the bolt sleeve, and then turn the long nut, at this time The pull rod will move in the upward direction, and the adjustment is good to tighten the screw sleeve.

3. Adjust or replace wearing parts in time

When the counter-attack broken hammer is worn to a certain degree, it should be adjusted and replaced in time to avoid damage to the fasteners and other components. When replacing consumables, pay attention to the methods. First open and put on the shelf. When in use, first remove the coupling bolts between the rear rack and the middle box, and then use a wrench to screw the hex head part of the clamshell device, and then the rack is slowly opened. At the same time, you can use the hanging device above the rack to hang to the rear rack. Repeat the above process, that is, close and put on the shelf.

4. Routine check bearing temperature of impact crusher

Real-time monitoring of how high the bearing temperature is, the excess or insufficient grease, whether the grease is dirty, and whether the bearing is damaged.

In summary, Chongqing Longjian Group recommends that everyone pay attention to the maintenance and maintenance of counter-breaking equipment in the operation of the machine-made sand production line, keep the problem girl in the bud, and do not lose it because of the small, fully guarantee the smooth operation of the machine-made sand production line . If you need to know more about counter-breaking equipment related knowledge, please call Chongqing Longjian Group: 400-023-0808, website: www.longjiangroup.cn.

-

Focus Project | With a total investment of 487 million yuan, The customer of Sanming Heavy Industry in Liuzhou, Guangxi will soon build an annual output of 4 million tons of fine sand aggregate production line

Focus Project | With a total investment of 487 million yuan, The customer of Sanming Heavy Industry in Liuzhou, Guangxi will soon build an annual output of 4 million tons of fine sand aggregate production line -

The 2022 Spring Festival holiday notice of Longjian Group

The 2022 Spring Festival holiday notice of Longjian Group -

Longjian Group held a virtual equity incentive promotion meeting in the fourth quarter of 2021

Longjian Group held a virtual equity incentive promotion meeting in the fourth quarter of 2021 -

Hand in hand to build heart to heart | Longjian Group Party branch went to Dashu Village to carry out "Urban and rural branches hand in hand" pair to build donation activities

Hand in hand to build heart to heart | Longjian Group Party branch went to Dashu Village to carry out "Urban and rural branches hand in hand" pair to build donation activities -

.png) Chongqing "Meter" high-speed Railway Network Construction | Full Construction in five years, Full operation in ten years -- Chengdu-Chongqing Middle Line high-speed railway Construction "Acceleration"

Chongqing "Meter" high-speed Railway Network Construction | Full Construction in five years, Full operation in ten years -- Chengdu-Chongqing Middle Line high-speed railway Construction "Acceleration" -

How to create green mines and green factories?

-

In the process of installation and acceptance of equipment of sand and gravel aggregate production line with production capacity of 600 tons at the beginning of construction in Hubei Province

In the process of installation and acceptance of equipment of sand and gravel aggregate production line with production capacity of 600 tons at the beginning of construction in Hubei Province -

Warmly congratulated: Mr. Long Fujian, chairman of the group company, was elected vice president of Chongqing sand and stone association

Warmly congratulated: Mr. Long Fujian, chairman of the group company, was elected vice president of Chongqing sand and stone association