At present, cone crusher has become a common crusher equipment. It is widely used in many fields such as mining, crushing of construction materials, road construction, etc. due to its advantages of high output, high proportion of fine materials, easy maintenance, and excellent grain shape.

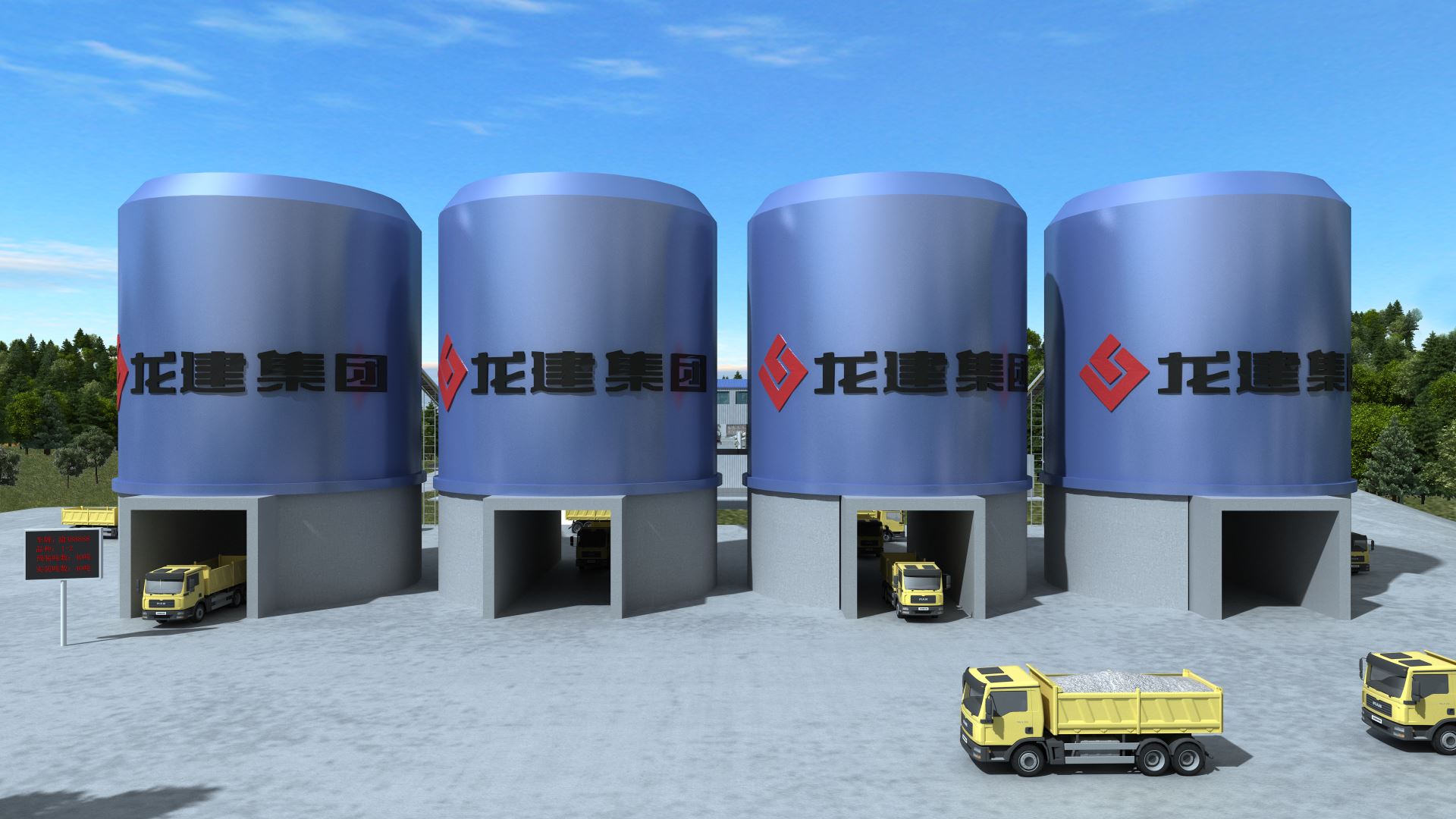

In order to further improve the performance of the cone crusher, Chongqing Longjian Industrial Group Co., Ltd. has launched a variety of cone crushers, PYB spring cone crusher series, FPB composite spring cone crusher series, DPH (S) single cylinder hydraulic cone crusher series, HPT multi-cylinder hydraulic cone crusher series and other products have won unanimous praise from users.

So how should friends of the cone crusher production line manage and use the cone crusher correctly? How to further improve the product effect of cone crusher? Senior editor of Chongqing Longjian Group Co., Ltd. to share with you ——

1. Run as full as possible

For the product of cone crusher, if it is "hungry" and "satisfactory" due to factors such as unstable feeding, then the product particle size and product rate will also fluctuate. Half-cavity running cones are not ideal in terms of gradation and needle shape.

Second, the feed should not be too small

For the cone crusher, giving a small amount of raw materials cannot continuously reduce the burden of the cone crusher. On the contrary, too little raw material will also damage the output of the cone crushed product, the particle size is not good, and adversely affect the cone broken bearings.

3. Keep the parameters of the tight-edge discharge port unchanged

In order to stabilize the output, quality and load of the production line of sand and gravel products, the parameters of the discharge port of the tight side of the cone crusher must be unchanged first. If the product particle size increases unexpectedly, it is easy to cause the final production capacity of the entire production line of the cone crusher.

4. Ensure that the falling point of the feed is aligned with the center point of the feed inlet

The senior editor of Longjian Group recommends that you use vertical deflectors to guide the falling point of the feed at the center of the cone breaking feed inlet. Once the drop point is eccentric, one side of the crushing chamber is full of material and the other side has no or little material, which will cause adverse impacts such as lower crusher throughput, increased needle-shaped products, and super-large particle size.

Fifth, ensure uniform feeding

When feeding, it is necessary to avoid the situation where large-diameter stones are concentrated on one side and small-diameter stones are concentrated on the other side, to ensure that the stones are mixed evenly.

Sixth, the stagnation of buffer silos is minimized

The buffer silo of the cone crusher is regarded as the "enemy of production", and the equipment and other related equipment also need to be carefully arranged.

7. Monitor and try to ensure proper speed of crusher

If the proper drive belt tension is not maintained, the drive maintenance is incorrect, or the drive maintenance is ignored, belt slippage and a drop in the speed of the crusher may occur during work. The throughput of the crusher's stone with a reduced speed has dropped sharply, while the power consumption has increased sharply, the unit energy consumption has increased, and operating costs have increased.

8. Controlling the fine material content in the feed

For secondary cone crushing, the fines content in the feed should not exceed 25%; the tertiary cone crushing should not exceed 10%.

Nine, the feeding height should not be too large

For small and medium-sized cone crushers, the maximum suitable height for the material to fall from the feeding equipment to the feed inlet is about 0.9 meters. If the feeding height is too large, the stone can easily "rush" into the crushing chamber at high speed, causing impact load on the crusher and adversely affecting it.

In summary, during the use of the cone crusher, equipment inspection and regular maintenance should be strengthened. Here, the editor of Longjian Group is willing to study and discuss with you. Welcome to call: 400-023-0808.

-

Focus Project | With a total investment of 487 million yuan, The customer of Sanming Heavy Industry in Liuzhou, Guangxi will soon build an annual output of 4 million tons of fine sand aggregate production line

Focus Project | With a total investment of 487 million yuan, The customer of Sanming Heavy Industry in Liuzhou, Guangxi will soon build an annual output of 4 million tons of fine sand aggregate production line -

The 2022 Spring Festival holiday notice of Longjian Group

The 2022 Spring Festival holiday notice of Longjian Group -

Longjian Group held a virtual equity incentive promotion meeting in the fourth quarter of 2021

Longjian Group held a virtual equity incentive promotion meeting in the fourth quarter of 2021 -

Hand in hand to build heart to heart | Longjian Group Party branch went to Dashu Village to carry out "Urban and rural branches hand in hand" pair to build donation activities

Hand in hand to build heart to heart | Longjian Group Party branch went to Dashu Village to carry out "Urban and rural branches hand in hand" pair to build donation activities -

.png) Chongqing "Meter" high-speed Railway Network Construction | Full Construction in five years, Full operation in ten years -- Chengdu-Chongqing Middle Line high-speed railway Construction "Acceleration"

Chongqing "Meter" high-speed Railway Network Construction | Full Construction in five years, Full operation in ten years -- Chengdu-Chongqing Middle Line high-speed railway Construction "Acceleration" -

How to create green mines and green factories?

-

In the process of installation and acceptance of equipment of sand and gravel aggregate production line with production capacity of 600 tons at the beginning of construction in Hubei Province

In the process of installation and acceptance of equipment of sand and gravel aggregate production line with production capacity of 600 tons at the beginning of construction in Hubei Province -

Warmly congratulated: Mr. Long Fujian, chairman of the group company, was elected vice president of Chongqing sand and stone association

Warmly congratulated: Mr. Long Fujian, chairman of the group company, was elected vice president of Chongqing sand and stone association